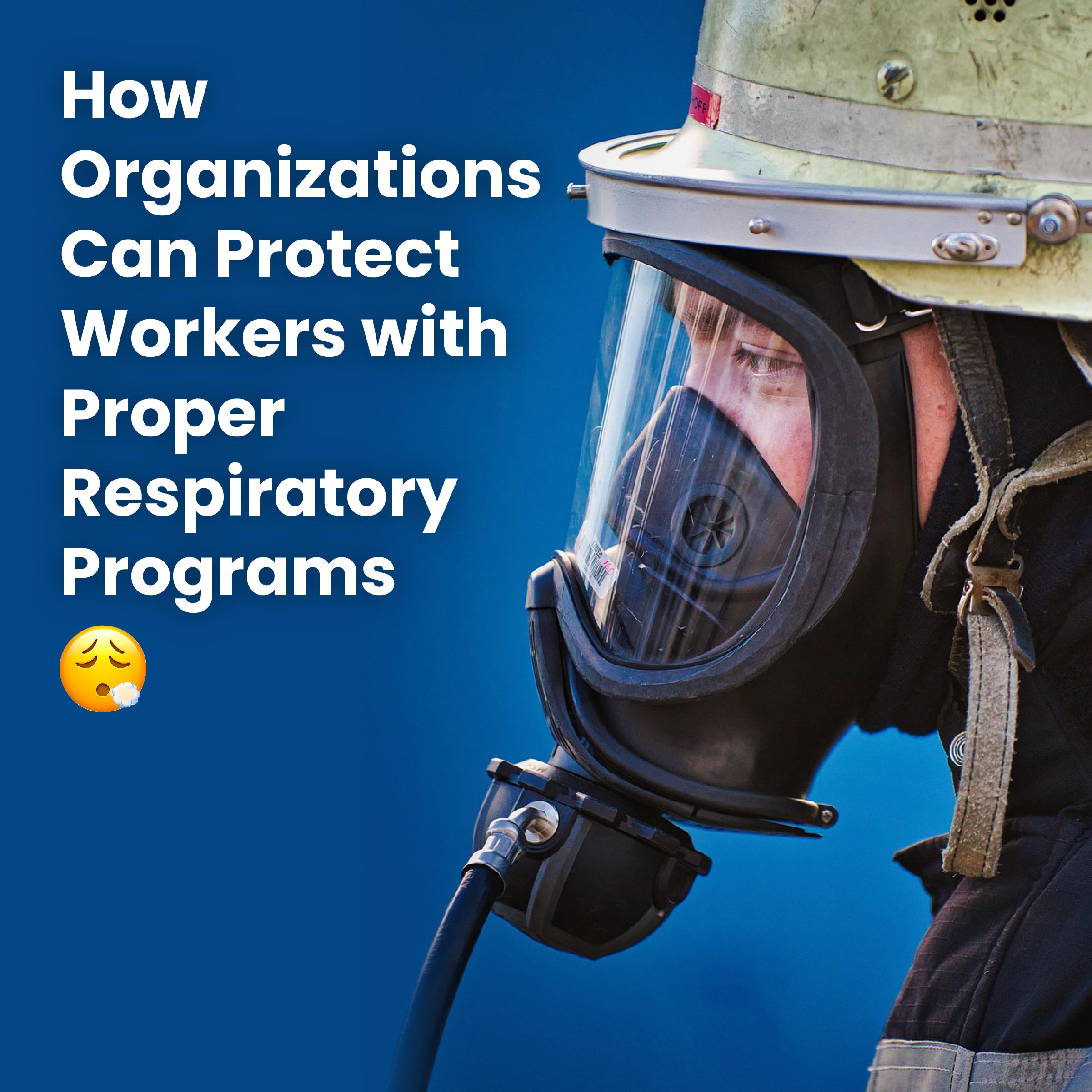

How Organizations Can Protect Workers with Proper Respiratory Programs

“Wait, what?! Respirators are supposed to protect my workers!” Yep, but they can also hurt your workers. It’s not as simple as pulling a respirator off the shelf at The Home Depot, screwing on the first filter you find a softball tossing it in the truck window as they drive off to a job. I’ll walk you through the process, it’s called Respirator Qualification The Respiratory Protection standard (29 CFR 1910.134) contains many requirements; however, these are the three essential requirements for qualifying employees to wear a respirator:

- Medical Qualification

- Respirator Training

- Respirator Fit Testing

Let’s address the burning question on everyone’s mind before we jump into qualification requirements:

“Why are respirators at the local hardware store available for me to purchase and use at home, but I must run through an obstacle course to wear one at work?”

The simple reason is that OSHA holds employers responsible for providing a safe work environment for employees. Respirators are an excellent tool to protect the lungs, but they can pose a health risk if misused. And it’s important to identify if the person wearing a respirator can handle the extra lung effort these devices require. This is why employers must ensure employees can safely wear a respirator at work. Respirator users are responsible for those decisions outside of work.

Now, back to the qualification requirements.

Step One: Medical Qualification

Medical qualifications for respirator use require a comprehensive evaluation of an employee’s health condition. OSHA is specific about the items that must be evaluated. This assessment determines an individual’s suitability for respirator use, as certain medical conditions may make it unsafe for an individual to use a respirator.

The medical evaluation can take many forms, but it always starts with a Medical Questionnaire using the items required in Appendix C of the standard. A Licensed Healthcare Professional (LHCP) reviews the questionnaire and depending on the answers, an individual may need additional medical evaluations before being deemed eligible to use a respirator. Employees who do not pass this stage cannot wear a respirator at work, and supervision must adjust their job duties accordingly.

Step Two: Respirator Training

It is vital to ensure that workers understand the respirator’s purpose, use, limitations, and potential hazards associated with use. Training can help reduce the risk of respiratory illnesses.

Respirator training typically involves a combination of classroom instruction and practical training.

Classroom Instruction typically includes an overview of the respirator’s design and function and a review of the workplace hazard assessment. It can be completed as computer-based training (CBT) or with an in person instructor.

Practical Instruction involves demonstrations and exercises to ensure the worker understands how to use the respirator correctly. This part is usually included as part of the fit test.

Whether you are building out the training program yourself or purchasing something off the shelf, ensure that employees can demonstrate the following:

- Why the respirator is necessary and how improper fit, usage, or maintenance can compromise the protective effect of the respirator

- The limitations and capabilities of the respirator

- How to use the respirator effectively in emergency situations, including situations in which the respirator malfunctions

- How to inspect, put on and remove, use, and check the seals of the respirator.

- Procedures for maintenance and storage of the respirator

- How to recognize medical signs and symptoms that may limit or prevent the effective use of respirators

Step Three: Respirator Fit Testing

Now that the employee knows how to wear a respirator safely and properly takes care of it, we must ensure it fits correctly, so contaminants are kept away from the employee’s lungs. There are two types of fit tests.

Quantitative Fit Test

- This type uses specialized equipment

- Measures the amount of leakage that occurs when the respirator is worn and compares it to the Protection Factor required by the respirator

- Produces a Fit Number

Qualitative Fit Test

- This type relies on the individual’s response to a test agent, such as a taste or smell, to determine if the respirator provides the necessary protection

OSH Professionals typically prefer Quantitative Fit Tests as they are objective measurements, whereas Qualitative Fit Tests rely on the subjective opinion of the individual being tested but they are convenient and require minimal effort to conduct.

During a fit test, the individual wearing the respirator will be asked to perform activities such as talking, breathing normally, and moving their head to check the fit and seal of the respirator. They may also be asked to wear the respirator to assess its comfort level.

A fit test helps identify gaps or loose areas where the respirator does not fit snugly against the face. This is how contaminants can enter the employee’s lungs and bypass the filters. This is why we ask employees to shave. Facial hair provides just enough space to let contaminants inside the respirator.

Ensure Organization-Wide Safety with Respirator Qualification

Respirator Qualification is an essential component of a Respiratory Protection Program, as it ensures that employees can safely use respirators in hazardous environments. The three crucial requirements for Respirator Qualification, Training, and Fit Testing – are critical to providing employees with the necessary protection from hazardous airborne contaminants. Organizations should ensure that their Respiratory Protection Program is current, that employees are medically cleared to wear a respirator, and that they understand how to use and take care of it correctly. With a comprehensive Respiratory Protection Program in place, companies can ensure the health and safety of their employees.

Ready to put your employees to the test? Sign up on YellowBird and post a Respirator Fit Test job today.

About YellowBird Pro Angela Ray:

Angela is a Certified Safety Professional (CSP) and a Safety Management Specialist (SMS). She began her career as an industrial Hygienist and has managed multiple Respiratory Protection Programs throughout her 25-year career. She passionately advocates for worker safety and firmly believes that business productivity and worker safety are simultaneously achievable.