Trusted to Deliver Safety Programs Nationwide

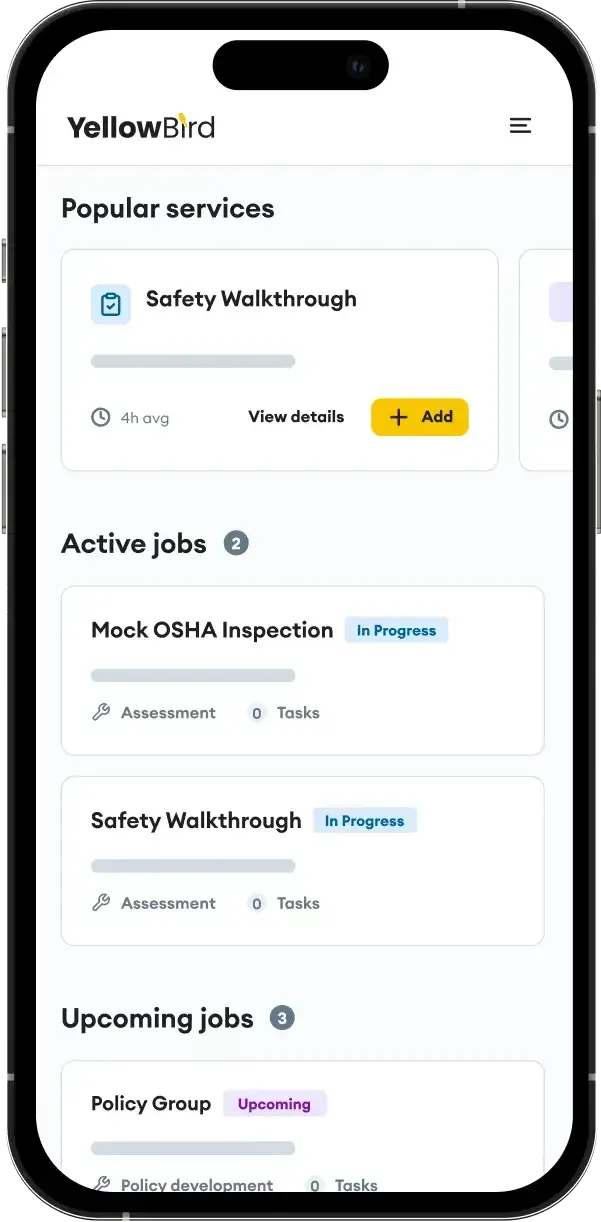

One platform. One request. Execute your safety program anytime, anywhere—without the paperwork.

Trusted by:

Get the Right Expert, Right Now

Speed

Match with qualified safety professionals in hours.

Expertise

Access a diverse network of certified safety professionals: safety specialists, OSHA trainers, EHS leaders, & more.

Flexibility

Hire for temporary staffing assignments, audits, training sessions, or ongoing compliance work.

Technology-Driven

Seamless, digital-first platform for sourcing, onboarding, and managing safety experts.

Customization

Specialists are selected based on experience, certifications, and past projects.

No Hidden Costs

Get matched with specialists in your area for one transparent cost. No surprise receipts.

Why Top Companies Choose YellowBird

On-Demand EHS & Risk Management Services for Enterprises

You can’t afford to guess when it comes to hiring risk management and safety experts. That’s why we don’t. At YellowBird, our AI-powered platform analyzes thousands of data points to rapidly connect you with elite, local safety professionals who specialize in your industry.

No swiping. No calling. No hiring headaches. Just the right safety expert, right now.

We know your reputation is on the line. That’s why we protect it. Every YellowBird Professional is pre-vetted, insured, and certified, so you can hire with confidence.

Most Popular Services

Forklift Training

Comprehensive program designed to equip individuals with the skills needed to safely operate a forklift.

Loss Control Audit

Comprehensive audit that evaluates safety protocols, risk controls, and regulatory compliance.

Policy Development

Assists organizations in developing comprehensive safety policies for multi-areas & mid-sized operations.

OSHA 10 Training

Entry-level OSHA training covering essential safety principles for every industry.

OSHA 30 Training

Comprehensive OSHA safety training for supervisors and workers with safety responsibilities.

Safety Walkthroughs

Proactively identify and correct workplace hazards with an expert-led safety walkthrough.

Fall Protection

Train workers to stay safe at heights with the skills and equipment needed to prevent falls before they happen.

Mock OSHA Inspection

Simulate an OSHA visit, spotting gaps before they turn into citations while building a safer workplace.

Trusted Safety Services

Industries That Rely on YellowBird

NEWS & INDUSTRY UPDATES